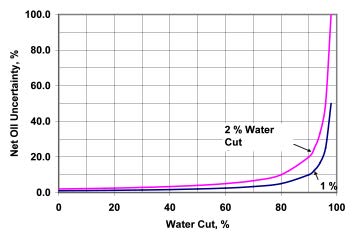

High water cut conditions can occur in water and steam flood productions as well as in mature reservoirs. Measurement uncertainty of Net Oil using a 2-Phase separator increases exponentially at high water cuts (>85%).

Enter 3-phase measurement

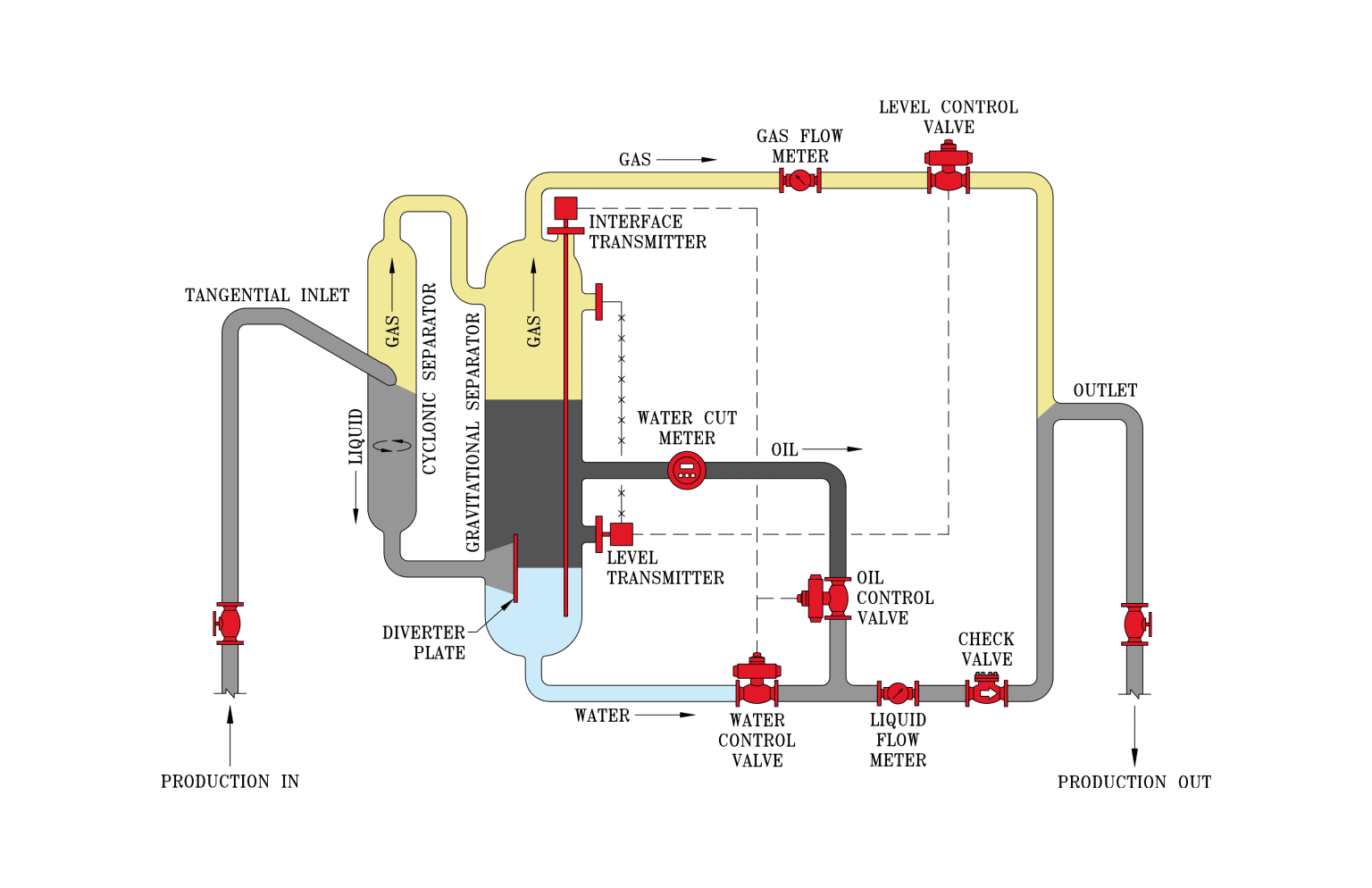

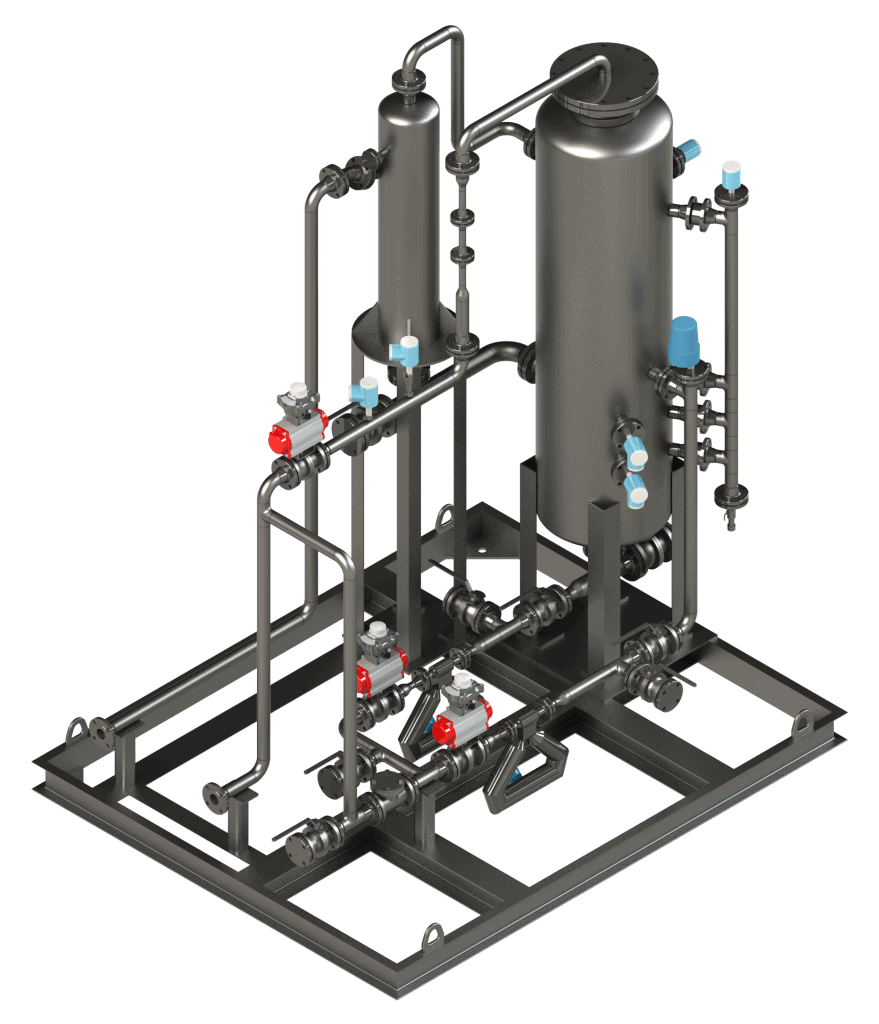

The Accuflow 3-Phase JR separation metering system addresses this issue of measurement uncertainty at high water cuts, by taking an additional step of separating water from oil. The Accuflow 3-Phase JR consists of an initial vertical pipe and a horizontal pipe section connected together as shown.

How It Works

Production fluid (oil, water, and gas) enters the vertical pipe tangentially, creating a cyclonic action in the pipe where the majority of the gas is separated and flows upward to the gas flow line above. The liquid then flows into a secondary vertical pipe section where free water is dropped out on the front side of a baffle plate. The baffle plate serves to prevent disturbance of the water/oil interface from the incoming fluid. On the backside of the baffle plate, the oil/water interface is monitored. Depending on the height of the interface, either the water leg will dump or the oil leg will dump.

For liquid measurement, a Coriolis meter is used to determine the flow rate and as well as a water cut meter in the oil leg to measure any remaining water in the emulsion. Gas is measured by typically either ultrasonic, vortex or Coriolis.

Features

- Measurement uncertainties:

- Water cut / water-liquid ratio (WLR): 0.25% absolute

- Liquid flow rate: 0.25% of reading

- Gas flow rate: 3% of reading

- Works in 0-100% GVF and all flow regimes

- 100% separation efficiency and complete separation of the gas and liquid phases

- Less than 5 psi / 0.3 bar pressure drop across entire skid

- Uses the most accurate flowmeter technologies (Coriolis for liquid, ultrasonic for gas) with high turndown ratios (>100:1)

- Water cut determination and flow corrections to standard according to API MPMS, ISO, and AGA standards

Benefits

- Smaller, lighter, lower cost, and lower maintenance than conventional well test separators

- High quality, continuous well test data with extra diagnostic data for:

- Evaluating reservoir properties, well performance, and fluid characteristics

- Production optimization

- Reservoir modeling

- Guiding economic decisions

- AI/ML model training